Creating a perfect miter joint in woodworking requires precision in cutting, fitting, and assembly. A miter joint is formed by joining two pieces of wood at an angle (typically 45° for a 90° corner). Here’s a step-by-step guide to achieving a flawless miter joint:

1. Tools & Materials Needed

Miter saw (or hand saw with a miter box)

Sharp, fine-toothed blade (for clean cuts)

Measuring tape & marking tools (pencil, marking knife)

Clamps (corner clamps or band clamps)

Wood glue (water-resistant for durability)

Sandpaper (120-220 grit)

Square (to check for accuracy)

Biscuit joiner or splines (optional for reinforcement)

2. Steps to a Perfect Miter Joint

Step 1: Measure & Mark Accurately

Determine the exact length needed for each piece.

Mark the cutting angle (usually 45° for a standard frame).

Use a marking knife for precision (prevents tear-out).

Step 2: Cut the Miter Accurately

Use a high-quality miter saw (or a well-tuned table saw with a miter gauge).

Ensure the saw blade is sharp and clean (dull blades cause tear-out).

Make test cuts on scrap wood to confirm the angle is correct.

For hand tools, use a miter box for stability.

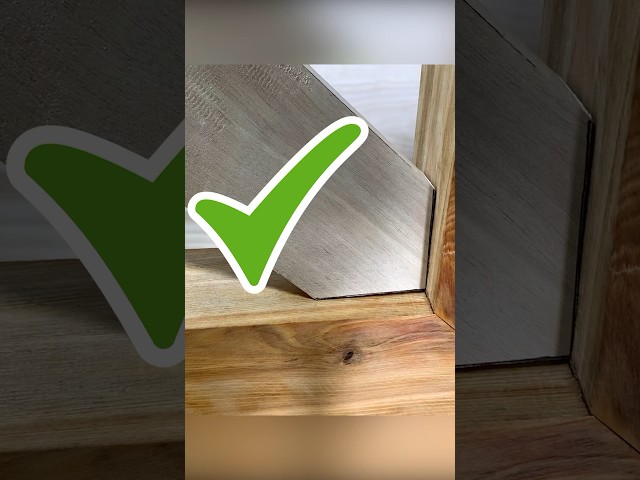

Step 3: Check the Fit

Dry-fit the pieces to ensure a tight, gap-free joint.

If gaps exist:

Recut (adjust the angle slightly if needed).

Sand the edges lightly for a better fit.

Step 4: Reinforce the Joint (Optional)

Biscuits/splines: Add small biscuits or splines for extra strength.

Dowel pins: Drill and insert dowels for alignment.

V-nails/keys: Used in picture frames for hidden reinforcement.

Step 5: Glue & Clamp Properly

Apply wood glue evenly on both mating surfaces.

Use corner clamps or a band clamp to hold the joint tightly.

Wipe off excess glue immediately with a damp cloth.

Allow the glue to dry fully (follow manufacturer’s time recommendation).

Step 6: Final Adjustments & Finishing

Sand the joint smoothly (start with 120 grit, finish with 220).

Fill any tiny gaps with wood filler (color-matched).

Apply stain, paint, or finish as desired.

3. Common Mistakes & Fixes

Gaps in the joint? → Recut or adjust the angle slightly.

Weak joint? → Reinforce with splines or dowels.

Tear-out? → Use masking tape on the cut line or a zero-clearance saw insert.

Misaligned corners? → Check for squareness with a framing square.

4. Pro Tips for Success

✔ Use a stop block for consistent cuts on multiple pieces.

✔ Shoot the edges with a hand plane for ultra-precise fits.

✔ Test on scrap wood before cutting expensive material.

✔ For picture frames, cut slightly longer and trim for final fit.