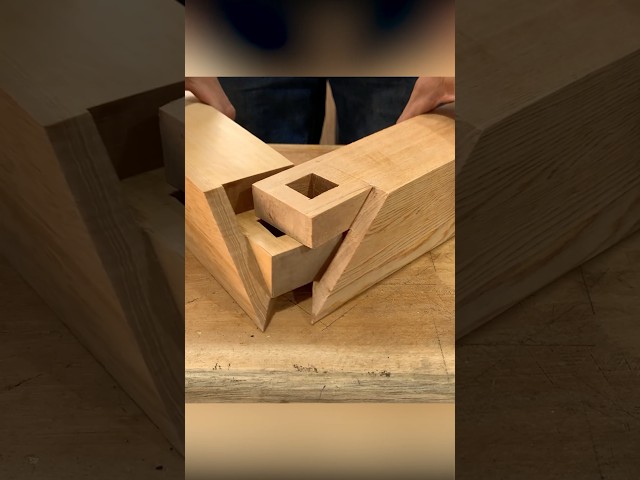

A strong mortise-and-tenon joint is one of the most reliable and aesthetically pleasing woodworking connections. Here’s how to create an amazing wood connection with a robust mortise:

1. Types of Mortise-and-Tenon Joints for Strength:

Through Mortise-and-Tenon – The tenon passes entirely through the mortise and is wedged or pinned for extra strength.

Haunched Mortise-and-Tenon – Adds a small shoulder (haunch) to prevent twisting, common in door frames.

Wedged Mortise-and-Tenon – The tenon is splayed and wedged to create a mechanical lock.

Tusk Tenon – Uses a tapered wedge for knockdown strength, often seen in timber framing.

Double/Twin Tenon – Two smaller tenons instead of one large one for wider boards (e.g., workbench legs).

2. Key Steps for a Strong Mortise:

Precise Layout – Use a marking gauge and square for accuracy.

Mortise Depth – Typically ⅔ to ¾ the thickness of the mortised piece.

Tenon Thickness – About ⅓ the thickness of the tenon piece (e.g., ¼" tenon in ¾" stock).

Tight Fit – The tenon should slide in snugly without forcing but not be loose.

3. Tools for Cutting a Mortise:

Chisel & Mallet (Traditional hand-cut method)

Mortising Machine (Hollow-chisel mortiser)

Drill Press + Chisel (For rough removal)

Router with Mortising Jig (Most precise for repeatability)

Festool Domino (Fast, loose-tenon alternative)

4. Reinforcing the Joint:

Glue (PVA or Epoxy) – Standard wood glue works, but epoxy fills gaps better.

Mechanical Fasteners – Drawbore pins, wedges, or screws for extra hold.

Floating Tenons – Domino or loose tenons for alignment ease.

5. Pro Tips for Maximum Strength:

Grain Alignment – Ensure the tenon grain runs long for strength.

Avoid Short Grain – Leave enough material around the mortise.

Clean Cuts – Sharp tools prevent tear-out and ensure tight fits.

Dry Fit First – Test before glue-up to avoid surprises.